Artificial Intelligence

Manufacturing

AI & SaaS for Energy Optimization in Manufacturing: Lowering Costs and Carbon Footprint

Energy consumption is a significant cost driver in manufacturing, and sustainability goals are becoming increasingly important for companies worldwide. AI-powered SaaS platforms are now enabling manufacturers to monitor, optimize, and reduce energy usage across production facilities, delivering both financial and environmental benefits.

What is AI-Driven Energy Optimization?

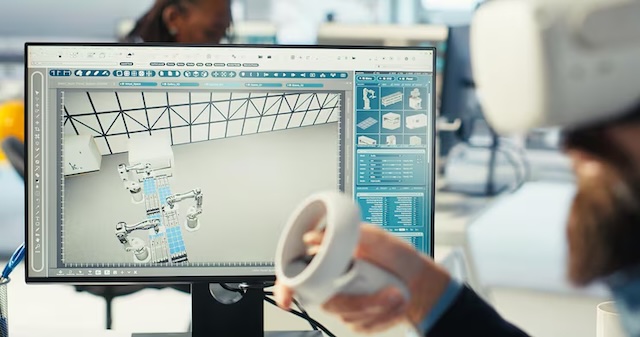

AI-driven energy optimization uses real-time data from machines, sensors, and IoT devices to analyze energy consumption patterns and identify inefficiencies. By applying machine learning algorithms, these platforms can recommend operational changes, automate adjustments, and predict energy peaks to reduce costs and environmental impact.

How SaaS Platforms Enable Energy Optimization

- Real-Time Monitoring: Track energy usage for machines, lines, or entire plants in real-time via cloud dashboards.

- Predictive Analytics: AI predicts periods of high energy consumption and suggests operational adjustments.

- Automated Control: SaaS platforms can autonomously adjust HVAC, lighting, and machine settings to optimize efficiency.

- Reporting and Compliance: Generate reports for sustainability goals, regulatory compliance, and carbon footprint tracking.

Applications in Manufacturing

- Peak Load Management: Shift non-critical processes to off-peak hours to reduce energy costs.

- Machine Efficiency Optimization: Identify underperforming machines or lines and suggest maintenance or operational changes.

- Renewable Energy Integration: Coordinate factory energy consumption with solar, wind, or other renewable sources.

- Carbon Footprint Tracking: Monitor emissions and energy sources to support sustainability reporting and ESG initiatives.

Benefits for Manufacturers

- Cost Reduction: Lower energy bills through optimized usage and peak-shifting strategies.

- Sustainability Compliance: Meet environmental standards and ESG goals more effectively.

- Operational Insights: Identify inefficiencies in equipment or processes that impact both energy consumption and productivity.

- Scalability: Cloud-based SaaS solutions allow multiple facilities to be monitored and optimized from a central platform.

Challenges and Considerations

- Data Accuracy: Reliable energy data is critical for AI models to produce actionable insights.

- Integration Complexity: Platforms must interface with a variety of machines, sensors, and legacy systems.

- Employee Training: Staff need to understand recommendations and trust AI-driven automation.

- Cost vs. ROI: Assess the potential savings against subscription and implementation costs.

The Future of Energy Optimization in Manufacturing

AI-enabled SaaS platforms are transforming energy management in manufacturing, combining cost savings with environmental responsibility. By continuously monitoring and optimizing energy usage, manufacturers can reduce operational costs, minimize carbon footprints, and achieve sustainability goals. As AI and IoT technologies advance, energy optimization will become a core component of smart, efficient, and environmentally-conscious manufacturing operations.